As we respond to the climate emergency, we must recognize that carbon emissions from our homes and buildings are not limited to their operational life. The emissions associated with the manufacturing, transportation, construction, and end-of-life phases of building materials, systems, and assemblies — commonly referred to as embodied carbon — also need to be factored into design of building retrofits.

Download the primer, or keep reading below.

Find more resources to help local governments accelerate deep retrofits.

Why embodied carbon matters

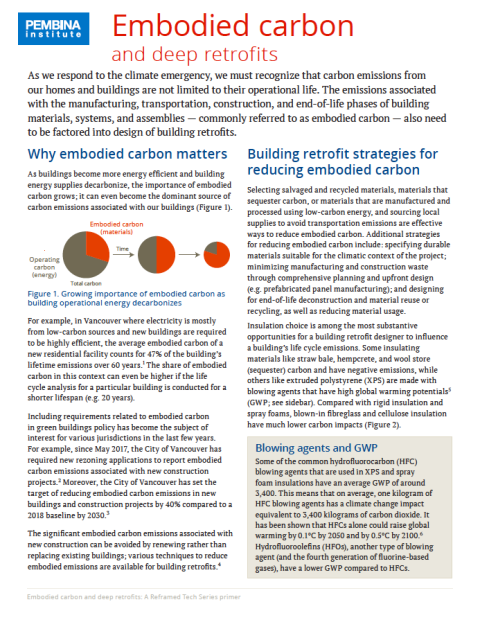

As buildings become more energy efficient and building energy supplies decarbonize, the importance of embodied carbon grows; it can even become the dominant source of carbon emissions associated with our buildings (Figure 1).

For example, in Vancouver where electricity is mostly from low-carbon sources and new buildings are required to be highly efficient, the average embodied carbon of a new residential facility counts for 47% of the building’s lifetime emissions over 60 years. The share of embodied carbon in this context can even be higher if the life cycle analysis for a particular building is conducted for a shorter lifespan (e.g. 20 years).

Including requirements related to embodied carbon in green buildings policy has become the subject of interest for various jurisdictions in the last few years. For example, since May 2017, the City of Vancouver has required new rezoning applications to report embodied carbon emissions associated with new construction projects. Moreover, the City of Vancouver has set the target of reducing embodied carbon emissions in new buildings and construction projects by 40% compared to a 2018 baseline by 2030. The significant embodied carbon emissions associated with new construction can be avoided by renewing rather than replacing existing buildings; various techniques to reduce embodied emissions are available for building retrofits.

Building retrofit strategies for reducing embodied carbon

Selecting salvaged and recycled materials, materials that sequester carbon, or materials that are manufactured and processed using low-carbon energy, and sourcing local supplies to avoid transportation emissions are effective ways to reduce embodied carbon. Additional strategies for reducing embodied carbon include: specifying durable materials suitable for the climatic context of the project; minimizing manufacturing and construction waste through comprehensive planning and upfront design (e.g. prefabricated panel manufacturing); and designing for end-of-life deconstruction and material reuse or recycling, as well as reducing material usage.

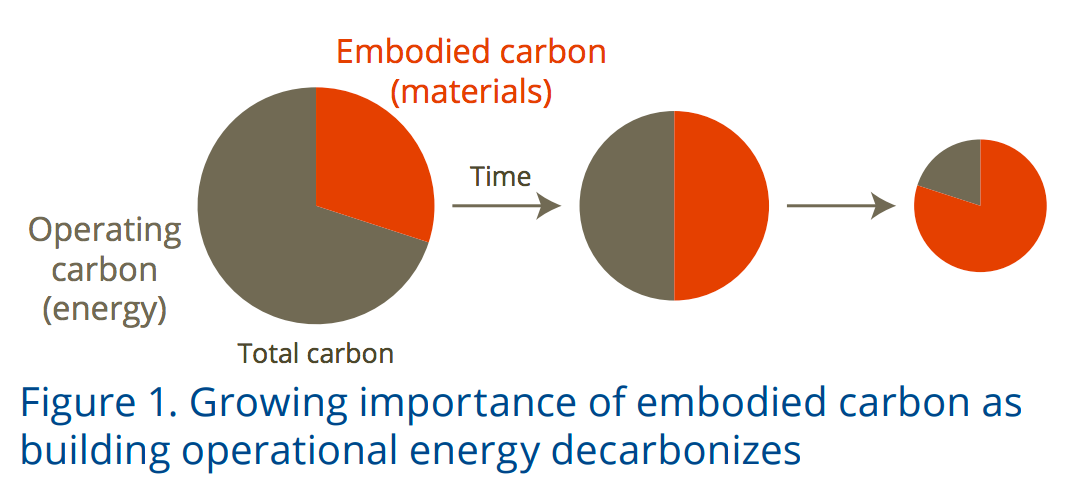

Insulation choice is among the most substantive opportunities for a building retrofit designer to influence a building’s life cycle emissions. Some insulating materials like straw bale, hempcrete, and wool store (sequester) carbon and have negative emissions, while others like extruded polystyrene (XPS) are made with blowing agents that have high global warming potentials (GWP; see sidebar). Compared with rigid insulation and spray foams, blown-in fibreglass and cellulose insulation have much lower carbon impacts (Figure 2).

Refrigerant choices also have material impacts on the carbon emissions associated with a building. HFC-134a is commonly used in air-conditioning systems; it has a GWP of 3,830 over a 20-year time horizon and GWP of 1,430 over 100 years. Some naturally occurring compounds that can be used as refrigerants, such as ammonia or propane, have much lower GWP. Refrigerant leakage rate is another important element that needs to be factored in when designing and selecting HVAC systems as it can have major impacts on a building’s life cycle carbon emissions.

Blowing agents and GWP

Some of the common hydrofluorocarbon (HFC) blowing agents that are used in XPS and spray foam insulations have an average GWP of around 3,400. This means that on average, one kilogram of HFC blowing agents has a climate change impact equivalent to 3,400 kilograms of carbon dioxide. It has been shown that HFCs alone could raise global warming by 0.1°C by 2050 and by 0.5°C by 2100. Hydrofluoroolefins (HFOs), another type of blowing agent (and the fourth generation of fluorine-based gases), have a lower GWP compared to HFCs.

Key considerations

- What are the barriers to designing with low-embodied-carbon materials and system components, and what market or policy drivers can move clients and design teams to include minimizing embodied carbon as a key project objective?

- What rationale should be used to set embodied carbon targets for building retrofit projects?

- How can we accelerate the adoption of low-GWP refrigerants?

- What are the disadvantages of using materials that are naturally low-carbon and/or sequester carbon, and how should these be considered when balancing their carbon benefits?

- How do we facilitate building design for end-of-life deconstruction and material reuse or recycling?

- How do we facilitate transparency on carbon intensity of proprietary materials?

Join a webinar

The Pembina Institute, in association with the Reframed Initiative, presents the Reframed Tech Series — webinars on evolving deep retrofit solutions. Watch our fifth webinar to hear from leaders in embodied carbon and retrofit solutions.

Reframed is an initiative of the BC Non-Profit Housing Association, the City of Vancouver, and the Pembina Institute. We're working to scale up deep retrofits for healthy, safe, and low-carbon housing. This is an opportunity for companies to showcase innovation and get in on the ground floor of a market transformation. Learn more.